Product Description

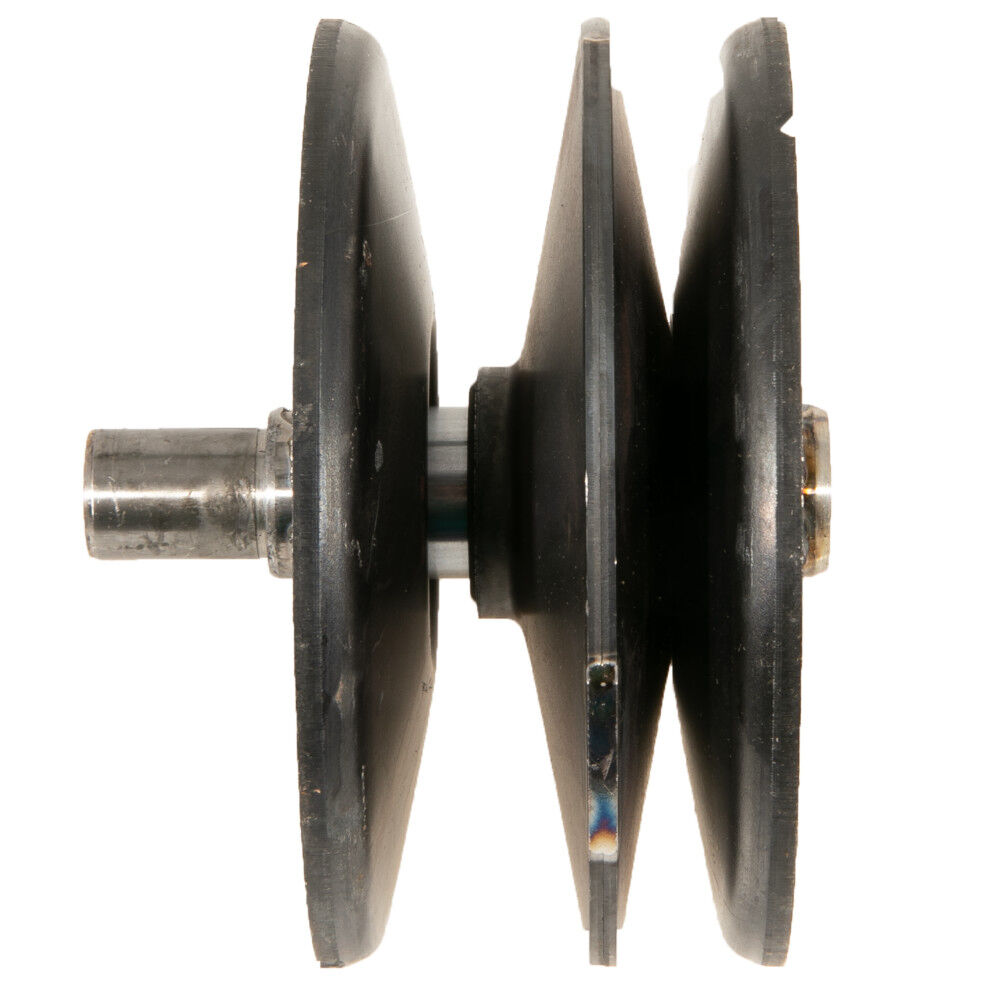

High quality SPC 8Groove 335mm v belt pulley for 4040 Taper Bush

We are a leading manafacturer of V Belt Pulley in China and ISO 9001 certificated.

V Belt Pulleys or “Vee Belt Pulleys” are specially constructed for V Belt and V Pulley systems using various section belts. These belts are used in several applications such as automobiles, wood working machines, etc. When used together with V Belts, they can guarantee top drive performances as well as high ratio and torque drives.

MIGHTY supply V Belts available with various sections, lengths, and materials. Our V Pulley range is available in A, B, C and Z belt sections, as well as in Taperlock or Pilot Bore fitment. We offer several V Belts with a wide range of diameters (50mm to 800mm), CHINAMFG or “grooves” (1 – 8), pitch diameters and forms.

If you are interested in finding our more about our industrial products, visit our products page, especially if you are in need of V Belt Pulleys and Timing pulleys. If you have any further queries or if you would like to know more about our Special Offers, contact us and we will be glad to help.

Can’t find what you’re looking for? – Contact us.

| Europe Standard: | SPZ, SPA, SPB, SPC V Belt Pulley |

| Bore: : | Taper bore pulley, Polit Bore pulley |

| Material: | Cast Iron GG25 |

| Surface treatment: | Phosphating finished |

| Lettering: | Laser typing |

Lead Time

| Quantity(Pieces) | 1 – 50 | 51 – 100 | 101 – 500 | >500 |

| Est. Time(days) | 15 | 30 | 50 | To be negotiated |

Each pulley is strictly static balanced with high precision machining tools. Unbalanced volume will corrected accurated.

Company Information

MIGHTY, a brand belongs to SCMC Corp. which is a wholly state-owned enterprise established in 1980, is specialized in producing precision mechanical power transmission products. After years of hard work, Mighty has already got the certificate of ISO9001:2000 and become a holding company of 3 manufacturing factories.

Mighty’s products are mainly exported to Europe, America and Middle East market. With the top-ranking management, professional technical support and abundant export experience, Mighty has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

Equipment: sawing machine, CNC Lathe, drilling machine, hobbing machine, punch machine, milling machine, gear shaper, grinding machine, machining center, etc.

Trade Show: PTC Asia, Canton Fair, Hannover Messe, IFPE

Main Products:

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking elements and shrink discs: could be alternative for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, etc.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical gear, bevel gear, worm gear, gear rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, normex coupling, FCL coupling, GE coupling, rigid and flexible coupling, jaw coupling, disc coupling, multi-beam coupling, universal joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Application

1. Engineering: machine tools, foundry equipments, conveyors, compressors, painting systems, etc.

2. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery machine, labeling machine, robots, etc.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm equipment, etc.

4. Texitile Mills: looms, spinning, wrappers, high-speed auto looms, processing machine, twister, carding machine, ruler calendar machine, high speed winder, etc.

5. Printing Machinery: newspaper press, rotary machine, screen printer machine, linotype machine offset printer, etc.

6. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation cell and chips saws, etc.

7. Building Construction Machinery: buffers, elevator floor polisher mixing machine, vibrator, hoists, crusher, etc.

8. Office Equipments: typewriter, plotters, camera, money drive, money sorting machine, data storage equipment, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, etc.

10. Home Appliances: vacuum cleaner, laundry machine, icecream machine, sewing machine, kitchen equipments, etc.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contacts

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

Any question or inquiry, pls contact us without hesitate, we assure any of your inquiry will get our prompt attention and reply!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Iron |

| Surface Treatment: | Polishing |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are some real-world examples of variable pulley applications in various industries?

Variable pulleys, also known as variable speed pulleys or adjustable pulleys, have diverse applications across various industries. Here are some real-world examples of how variable pulleys are used:

1. Automotive Industry:

In the automotive industry, variable pulleys are commonly used in continuously variable transmissions (CVTs). CVTs utilize toroidal or continuously variable pulleys to provide seamless and efficient variation of the gear ratio in vehicles. This allows for optimal engine performance across different driving conditions, resulting in improved fuel efficiency and smoother acceleration.

2. Industrial Machinery:

Variable pulleys find extensive applications in industrial machinery, where adjustable speed and power transmission are crucial. They are used in machinery such as milling machines, lathes, drill presses, and conveyor systems. By adjusting the position of the belt or changing the effective diameter of the pulley, variable pulleys enable operators to control the speed and torque output, facilitating versatile and efficient operation.

3. Exercise Equipment:

Treadmills, elliptical trainers, and stationary bikes are examples of exercise equipment that utilize variable pulleys. These pulleys allow users to control the speed and intensity of their workouts, providing a customizable and challenging exercise experience. By adjusting the position of the variable pulleys, users can increase or decrease the resistance, simulate different terrains, or vary the workout programs, enhancing the effectiveness of the workout.

4. Textile Industry:

In the textile industry, variable pulleys are used in various textile machines such as spinning machines, weaving looms, and knitting machines. These pulleys enable operators to adjust the speed and tension of the belts and threads, ensuring precise control over the production process and optimizing the quality of the textile products.

5. Power Transmission Systems:

Variable pulleys play a critical role in power transmission systems, where the speed and torque requirements can vary. They are used in applications such as conveyors, pumps, compressors, and fans, allowing for efficient power transmission and the ability to adjust the speed according to the specific needs of the system.

6. Woodworking Industry:

Woodworking equipment, such as table saws, band saws, and planers, often utilize variable pulleys. These pulleys enable operators to adjust the cutting speed and optimize the performance based on the type of wood and the desired outcome. By changing the position of the belt or adjusting the effective diameter of the pulley, woodworkers can achieve precise control over their cutting operations.

These examples demonstrate the widespread use of variable pulleys in various industries. Their ability to provide adjustable speed, torque, and power transmission makes them valuable components in machinery and equipment, enabling flexibility, efficiency, and improved performance.

How does the adjustment of a variable pulley affect its performance?

The adjustment of a variable pulley has a significant impact on its performance and the overall performance of the system it is incorporated into. Let’s explore how the adjustment of a variable pulley affects its performance:

1. Speed Control:

By adjusting the position of the movable pulley half, the effective diameter of the pulley system is changed. This adjustment directly affects the speed control capability of the variable pulley. When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases, resulting in a higher speed ratio between the input and output shafts. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a lower speed ratio. Therefore, the adjustment of the variable pulley allows for precise speed control, enabling the system to operate at the desired speed for a given task.

2. Power Transmission:

The adjustment of a variable pulley also affects power transmission in the system. By changing the speed ratio, the variable pulley adjusts the rotational speed of the output shaft relative to the input shaft. This adjustment has an impact on the torque and power characteristics of the system. When the variable pulley is adjusted to provide a lower speed ratio, it increases the torque at the output shaft, allowing the system to handle higher loads or perform tasks requiring higher torque. Conversely, when the variable pulley is adjusted to provide a higher speed ratio, it sacrifices some torque in favor of increased rotational speed. This trade-off between torque and speed transmission allows for optimization of power transmission in different operating conditions.

3. Efficiency:

The adjustment of a variable pulley can also affect the efficiency of the system. By optimizing the speed ratio, the variable pulley helps the system operate at its most efficient point. In applications where energy efficiency is crucial, such as automotive systems or industrial machinery, adjusting the variable pulley to achieve the desired speed can minimize energy waste and improve overall system efficiency.

4. Belt Tension and Grip:

Proper adjustment of the variable pulley ensures optimal belt tension and grip. When the pulley halves are adjusted correctly, it ensures that the belt or chain is properly tensioned, preventing slippage and ensuring efficient power transmission. Improper adjustment can lead to belt slipping, reduced power transmission, and increased wear on the belt and pulley surfaces.

5. Smooth Transitions:

The adjustment mechanism associated with the variable pulley allows for smooth transitions between different speed ratios. Precise and controlled movement of the movable pulley half ensures gradual adjustments in the effective diameter, resulting in seamless speed changes without sudden jolts or disturbances in power transmission. This smooth transition capability enhances the overall performance and reliability of the system.

It’s important to note that the adjustment of a variable pulley should be done according to the manufacturer’s guidelines and specifications. Improper adjustment can result in suboptimal performance, increased wear, and reduced system efficiency. Regular maintenance and inspection of the variable pulley are also essential to ensure its continued performance and reliability.

What types of belts are typically employed with variable pulleys?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, are compatible with various types of belts. The choice of belt depends on factors such as the specific application, power transmission requirements, and environmental conditions. Here are some types of belts commonly employed with variable pulleys:

1. V-Belts:

V-belts are one of the most common types of belts used with variable pulleys. They have a trapezoidal cross-section and are designed to fit into V-shaped grooves on the pulley halves. V-belts are known for their high friction grip, which allows for efficient power transmission. They can handle moderate to high-speed ratios and are suitable for applications requiring reliable power transfer.

2. Flat Belts:

Flat belts have a rectangular cross-section and are widely used with variable pulleys. They offer flexibility and are capable of transmitting high power loads. Flat belts typically have fabric or rubber coatings on both sides to enhance grip and prevent slippage. They are commonly used in applications where a wide speed range and high torque transmission are required.

3. Timing Belts:

Timing belts, also known as synchronous belts, are toothed belts that mesh with corresponding teeth on the pulley halves. They provide precise power transmission and are often used in applications where accurate timing and synchronization are critical. Timing belts are commonly employed in automotive engines, robotics, and other precision machinery.

4. Poly-V Belts:

Poly-V belts, also called multi-rib belts, have multiple V-shaped ribs on the inner surface. They are designed to fit into corresponding grooves on the pulleys. Poly-V belts offer high power transmission capabilities and are suitable for applications that require compact designs and high-speed ratios. They are commonly used in automotive accessory drives, such as alternator and power steering systems.

5. Round Belts:

Round belts, as the name suggests, have a circular cross-section and are commonly made of rubber or urethane materials. They provide flexibility and are often used in applications that require minimal vibration and noise. Round belts are suitable for light to moderate power transmission and are commonly used in applications such as office equipment, textile machinery, and small appliances.

It’s important to note that the selection of the appropriate belt for a variable pulley should consider factors such as load requirements, speed range, temperature constraints, and environmental conditions. Consulting the manufacturer’s specifications and recommendations can help ensure the optimal belt choice for a given application.

editor by CX

2024-04-03