Product Description

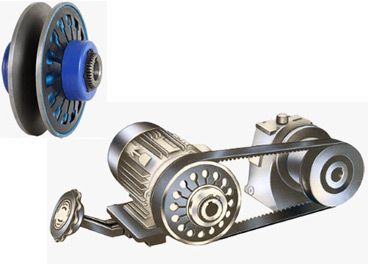

High quality SPC 8Groove 335mm v belt pulley for 4040 Taper Bush

We are a leading manafacturer of V Belt Pulley in China and ISO 9001 certificated.

V Belt Pulleys or “Vee Belt Pulleys” are specially constructed for V Belt and V Pulley systems using various section belts. These belts are used in several applications such as automobiles, wood working machines, etc. When used together with V Belts, they can guarantee top drive performances as well as high ratio and torque drives.

MIGHTY supply V Belts available with various sections, lengths, and materials. Our V Pulley range is available in A, B, C and Z belt sections, as well as in Taperlock or Pilot Bore fitment. We offer several V Belts with a wide range of diameters (50mm to 800mm), CHINAMFG or “grooves” (1 – 8), pitch diameters and forms.

If you are interested in finding our more about our industrial products, visit our products page, especially if you are in need of V Belt Pulleys and Timing pulleys. If you have any further queries or if you would like to know more about our Special Offers, contact us and we will be glad to help.

Can’t find what you’re looking for? – Contact us.

| Europe Standard: | SPZ, SPA, SPB, SPC V Belt Pulley |

| Bore: : | Taper bore pulley, Polit Bore pulley |

| Material: | Cast Iron GG25 |

| Surface treatment: | Phosphating finished |

| Lettering: | Laser typing |

Lead Time

| Quantity(Pieces) | 1 – 50 | 51 – 100 | 101 – 500 | >500 |

| Est. Time(days) | 15 | 30 | 50 | To be negotiated |

Each pulley is strictly static balanced with high precision machining tools. Unbalanced volume will corrected accurated.

Company Information

MIGHTY, a brand belongs to SCMC Corp. which is a wholly state-owned enterprise established in 1980, is specialized in producing precision mechanical power transmission products. After years of hard work, Mighty has already got the certificate of ISO9001:2000 and become a holding company of 3 manufacturing factories.

Mighty’s products are mainly exported to Europe, America and Middle East market. With the top-ranking management, professional technical support and abundant export experience, Mighty has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

Equipment: sawing machine, CNC Lathe, drilling machine, hobbing machine, punch machine, milling machine, gear shaper, grinding machine, machining center, etc.

Trade Show: PTC Asia, Canton Fair, Hannover Messe, IFPE

Main Products:

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking elements and shrink discs: could be alternative for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, etc.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical gear, bevel gear, worm gear, gear rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, normex coupling, FCL coupling, GE coupling, rigid and flexible coupling, jaw coupling, disc coupling, multi-beam coupling, universal joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Application

1. Engineering: machine tools, foundry equipments, conveyors, compressors, painting systems, etc.

2. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery machine, labeling machine, robots, etc.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm equipment, etc.

4. Texitile Mills: looms, spinning, wrappers, high-speed auto looms, processing machine, twister, carding machine, ruler calendar machine, high speed winder, etc.

5. Printing Machinery: newspaper press, rotary machine, screen printer machine, linotype machine offset printer, etc.

6. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation cell and chips saws, etc.

7. Building Construction Machinery: buffers, elevator floor polisher mixing machine, vibrator, hoists, crusher, etc.

8. Office Equipments: typewriter, plotters, camera, money drive, money sorting machine, data storage equipment, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, etc.

10. Home Appliances: vacuum cleaner, laundry machine, icecream machine, sewing machine, kitchen equipments, etc.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contacts

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

Any question or inquiry, pls contact us without hesitate, we assure any of your inquiry will get our prompt attention and reply!

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Iron |

| Surface Treatment: | Polishing |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with variable pulleys?

When working with variable pulleys, it is important to keep several safety considerations in mind to ensure the well-being of individuals and prevent accidents. Here are some key safety considerations:

- Proper training: Only trained and authorized personnel should operate or work with variable pulleys. They should have a thorough understanding of the equipment, its functions, and the associated hazards. Training should cover topics such as proper usage, maintenance, and emergency procedures.

- Equipment inspection: Before using variable pulleys, it is crucial to inspect them for any signs of damage or wear. Check for issues such as frayed cables, loose bolts, or misalignment. If any defects are found, the pulleys should be taken out of service until repairs or replacements are made.

- Personal protective equipment (PPE): Workers should wear appropriate PPE, such as safety goggles, gloves, and protective clothing, to prevent injuries from flying debris, pinch points, or accidental contact with moving parts.

- Secure footing: Ensure that the work area around the variable pulleys is clean, well-lit, and free from any obstructions. Maintain good footing and position yourself in a stable manner to avoid slips, trips, and falls.

- Guarding: Install appropriate guards or barriers around the pulleys to prevent accidental contact with moving parts. This can include safety covers or enclosures that restrict access to the pulleys during operation.

- Lockout/tagout: Implement lockout/tagout procedures to control hazardous energy sources when performing maintenance or repairs on variable pulleys. This ensures that the equipment is properly shut down, isolated, and cannot be unintentionally started.

- Weight capacity: Always adhere to the weight capacity limits specified by the manufacturer. Overloading the pulleys can lead to equipment failure, loss of control, or structural damage.

- Proper use: Follow the manufacturer’s instructions and guidelines for the appropriate use of variable pulleys. Avoid using them for tasks or loads they are not designed for, as this can pose safety risks.

- Regular maintenance: Perform routine inspections, cleaning, and maintenance of the variable pulleys as recommended by the manufacturer. This helps identify potential issues early on and ensures the equipment operates safely and efficiently.

- Emergency preparedness: Have emergency procedures in place, including knowledge of emergency stops, shutdown procedures, and how to respond to accidents or malfunctions involving variable pulleys. Workers should be aware of evacuation routes and have access to communication devices for summoning help if needed.

What role do variable pulleys play in achieving variable speed control in machinery?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, play a crucial role in achieving variable speed control in machinery. They provide a means to adjust the speed ratio between the input and output shafts, allowing for precise control of rotational speed. Here’s how variable pulleys enable variable speed control:

1. Speed Adjustment:

Variable pulleys consist of two pulley halves: a fixed pulley half and a movable pulley half. The movable pulley half can be adjusted along the axis of the shaft, changing its effective diameter. By altering the position of the movable pulley half, the speed ratio between the input and output shafts can be modified. When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases, resulting in a higher speed ratio. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a lower speed ratio. This adjustability allows for fine-tuning of the speed control in machinery.

2. Continuous Speed Variation:

Unlike fixed-speed pulleys or gear systems with discrete speed settings, variable pulleys offer continuous speed variation. The adjustment mechanism associated with variable pulleys enables smooth and seamless transitions between different speed ratios. By precisely positioning the movable pulley half, the desired speed can be achieved without the need for manual gear changes or transmission adjustments. This continuous speed variation capability allows machinery to operate at optimal speeds for different tasks or operating conditions.

3. Energy Efficiency:

Variable pulleys contribute to energy efficiency in machinery. By providing adjustable speed control, they allow the system to operate at the most efficient speed for a given task. This optimization minimizes energy waste and reduces unnecessary power consumption. For example, in applications such as HVAC systems or industrial machinery, variable pulleys enable the motor or engine to operate at the most efficient speed, resulting in improved energy efficiency and reduced operating costs.

4. Load Adaptation:

Variable pulleys facilitate load adaptation in machinery. By adjusting the speed ratio, the torque and power characteristics of the system can be optimized to match the specific load requirements. When higher torque is needed, the variable pulley can be adjusted to provide a lower speed ratio, allowing the system to handle heavier loads. Conversely, when speed is a priority, the variable pulley can be adjusted to provide a higher speed ratio, sacrificing some torque in favor of increased rotational speed. This load adaptation capability allows machinery to effectively handle varying load conditions.

5. Control Precision:

Variable pulleys offer precise speed control, enabling machinery to meet specific speed requirements with high precision. The fine adjustments in the effective diameter allow for accurate and controlled speed setting. This level of control precision is particularly advantageous in applications where precise speed synchronization, timing, or regulation is critical, such as in robotics, conveyor systems, or automated manufacturing processes.

By providing adjustable speed control, continuous speed variation, energy efficiency, load adaptation, and control precision, variable pulleys play a vital role in achieving variable speed control in machinery. Their flexibility and ability to fine-tune speed ratios contribute to improved performance, productivity, and efficiency in various industrial and mechanical applications.

What is a variable pulley, and how does it function in mechanical systems?

A variable pulley, also known as a variable speed pulley or a variable drive pulley, is a type of pulley designed to provide variable speed ratios in mechanical systems. It consists of two or more pulley halves that can move relative to each other, allowing for adjustment of the effective diameter and thus changing the speed ratio between the input and output shafts.

The primary function of a variable pulley is to provide a means of continuously adjusting the speed of driven components in a mechanical system without the need for manual gear changes or transmission adjustments. This flexibility is particularly useful in applications where speed variations are required to accommodate different load conditions or to achieve specific operational requirements.

The operation of a variable pulley is based on the principle of changing the effective diameter that the belt or chain engages with. It typically consists of a fixed pulley half and a movable pulley half, both connected by a belt or chain. The movable pulley half is designed to slide or pivot, which changes the distance between the pulley halves, thus altering the effective diameter.

When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases. This results in a larger belt or chain contact area and a higher speed ratio between the input and output shafts. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a smaller contact area and a lower speed ratio.

Variable pulleys can be actuated by different mechanisms, such as hydraulic, pneumatic, or mechanical means. The actuation mechanism allows for precise adjustment of the movable pulley position, enabling smooth speed transitions and accurate control.

One common application of variable pulleys is in automotive vehicles, where they are used in continuously variable transmissions (CVTs). In a CVT, the variable pulleys provide seamless speed adjustments, allowing the engine to operate at its optimal speed for different driving conditions, resulting in improved fuel efficiency and performance.

In summary, a variable pulley is a pulley system that enables continuous adjustment of speed ratios in mechanical systems. By changing the effective diameter through the movement of pulley halves, it allows for variable speed control without the need for manual gear changes. Variable pulleys find applications in various industries, providing flexibility, efficiency, and precise speed control in mechanical systems.

editor by CX

2023-12-14