Product Description

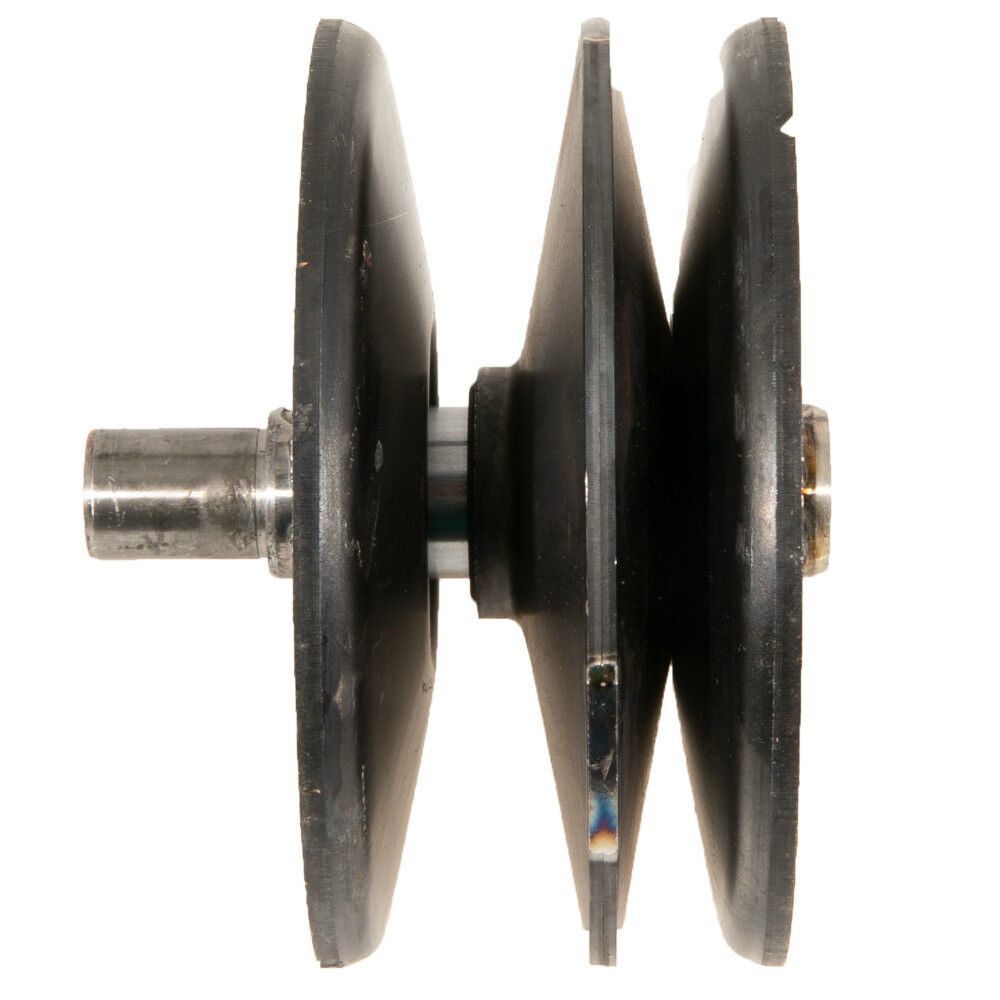

3B Gripbelt Sheaves pulley with Split Taper Bushings for Use with All A and B Section Belts

Product Description

3B series pulleys are manufactured for A, AX, AA, 4L, B, BX, BB, and 5L v-belts, ranging from 5.75″ to 38.35″ in diameter. Depending on the pulley size, they are made to use with R1 taper bushings or Q1 taper bushings, which we also stock. Most of our three-groove 3B split taper bushed pulleys are manufactured from a high-strength grade 35 cast iron, are phosphate-coated, and are painted for anti-corrosion. All of them are balanced at the factory for smooth machinery operation.

Product Parameters

|

Size |

Bushing Type |

Pitch Diameter (A/ 4L) |

Pitch Diameter (B/ 5L) |

Outside Diameter |

Type |

(O.L.) |

(L) |

(P) |

(C) |

(H) |

(F) |

(G) |

(X) |

(E) |

Weight (LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3B54Q | Q1 | 5.0″ | 5.4″ | 5.75″ | 5 | 3-17/32″ | 2-1/2″ | 3/4″ | 3/4″ | 4-1/8″ | 2-1/2″ | — | 1-3/4″ | 9/32″ | 7.9 |

| 3B56Q | Q1 | 5.2″ | 5.6″ | 5.95″ | 5 | 3-17/32″ | 2-1/2″ | 3/4″ | 3/4″ | 4-1/8″ | 2-1/2″ | — | 1-3/4″ | 9/32″ | 9.0 |

| 3B58Q | Q1 | 5.4″ | 5.8″ | 6.15″ | 13 | 3-5/32″ | 2-1/2″ | 3/8″ | 3/8″ | 4-1/8″ | 2-1/2″ | 3/4″ | 1-3/4″ | 9/32″ | 9.4 |

| 3B60Q | Q1 | 5.6″ | 6.0″ | 6.35″ | 13 | 3-5/32″ | 2-1/2″ | 3/8″ | 3/8″ | 4-1/8″ | 2-1/2″ | 3/4″ | 1-3/4″ | 9/32″ | 10.4 |

| 3B62Q | Q1 | 5.8″ | 6.2″ | 6.55″ | 13 | 3-5/32″ | 2-1/2″ | 3/8″ | 3/8″ | 4-1/8″ | 2-1/2″ | 3/4″ | 1-3/4″ | 9/32″ | 11.3 |

| 3B64Q | Q1 | 6.0″ | 6.4″ | 6.75″ | 13 | 3-5/32″ | 2-1/2″ | 3/8″ | 3/8″ | 4-1/8″ | 2-1/2″ | 3/4″ | 1-3/4″ | 9/32″ | 12.1 |

| 3B66Q | Q1 | 6.2″ | 6.6″ | 6.95″ | 13 | 3-5/32″ | 2-1/2″ | 3/8″ | 3/8″ | 4-1/8″ | 2-1/2″ | 3/4″ | 1-3/4″ | 9/32″ | 13.0 |

| 3B68Q | Q1 | 6.4″ | 6.8″ | 7.15″ | 13 | 3-5/32″ | 2-1/2″ | 3/8″ | 3/8″ | 4-1/8″ | 2-1/2″ | 3/4″ | 1-3/4″ | 9/32″ | 14.3 |

| 3B154R | R1 | 15.0″ | 15.4″ | 15.75″ | 13 | 3-13/32″ | 2-7/8″ | 5/8″ | 1/4″ | 5-3/8″ | 2-1/2″ | 7/8″ | 2″ | 9/32″ | 35.5 |

| 3B160R | R1 | 15.6″ | 16.0″ | 16.35″ | 13 | 3-13/32″ | 2-7/8″ | 5/8″ | 1/4″ | 5-3/8″ | 2-1/2″ | 7/8″ | 2″ | 9/32″ | 38.0 |

| 3B184R | R1 | 18.0″ | 18.4″ | 18.75″ | 13 | 3-13/32″ | 2-7/8″ | 5/8″ | 1/4″ | 5-3/8″ | 2-1/2″ | 7/8″ | 2″ | 9/32″ | 44.8 |

| 3B200R | R1 | 19.5″ | 20.0″ | 20.35″ | 13 | 3-13/32″ | 2-7/8″ | 5/8″ | 1/4″ | 5-3/8″ | 2-1/2″ | 7/8″ | 2″ | 9/32″ | 50.3 |

| 3B250R | R1 | 24.5″ | 25.0″ | 25.35″ | 13 | 3-13/32″ | 2-7/8″ | 5/8″ | 1/4″ | 5-3/8″ | 2-1/2″ | 7/8″ | 2″ | 9/32″ | 65.0 |

| 3B300R | R1 | 29.5″ | 30.0″ | 30.35″ | 13 | 3-13/32″ | 2-7/8″ | 5/8″ | 1/4″ | 5-3/8″ | 2-1/2″ | 7/8″ | 2″ | 9/32″ | 89.0 |

| 3B380R | R1 | 37.5″ | 38.0″ | 38.35″ | 13 | 3-13/32″ | 2-7/8″ | 5/8″ | 1/4″ | 5-3/8″ | 2-1/2″ | 7/8″ | 2″ | 9/32″ | 106.0 |

Company Profile

HZPT is a professional manufacturer of mechanical parts. Our main products are belt pulleys, sprockets, taper sleeves, coupling, and other transmission parts. Its products are mainly exported to Germany, Britain, France, and other European countries, with an annual export value of 18 million US dollars, accounting for more than 65% of the total output. The annual output value reached 200 million yuan.

Our products all adopt international, European, and American advanced industrial standards, use precise and good processing equipment, develop reasonable production technology, apply efficient and flexible management systems, and improve the quality management system to ensure that the product quality is good and the price is affordable.

Our factory adheres to the enterprise concept of “quality: the basis of enterprise survival, integrity: the basis of enterprise development, service: the source of enterprise development, low price: the instrument of enterprise development.” We are always looking CHINAMFG to the presence of customers at home and abroad, seeking CHINAMFG benefits and joint cause development.

Warehouse Stock

The warehouse covers an area of 5000 square CHINAMFG and can provide all kinds of standard models A/B/C/Z, with complete quantity and large quantity in stock. Meanwhile, it accepts all sorts of non-standard customization for drawing production. The daily production capacity is 10 tons, and the delivery time is short.

Packaging & Shipping

Experienced Workers Packing Pulleys Carefully, safe wooden cases keep parts from being injured or damaged during sea or air shipment.

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How do you select the right variable pulley configuration for a specific task?

Selecting the right variable pulley configuration for a specific task involves considering several factors. Here are the key steps in the selection process:

1. Define the Requirements:

Start by clearly defining the requirements of the task or application. Determine the desired speed range, torque, power transmission capacity, and any specific control requirements.

2. Evaluate Speed Variation:

Assess the required speed variation range. Consider whether a stepless or stepped speed variation is needed and determine the desired number of speed settings.

3. Consider Torque and Power:

Evaluate the torque and power requirements of the task. Calculate the maximum torque and power that the variable pulley configuration needs to handle to ensure reliable and efficient operation.

4. Assess Space and Installation Constraints:

Consider the available space for the variable pulley configuration and any installation constraints. Evaluate the physical dimensions, mounting options, and compatibility with the existing machinery or equipment.

5. Determine Adjustability and Control:

Determine the level of adjustability and control required for the task. Assess whether manual adjustment or automated control is needed, and consider the ease of adjustment and precision required.

6. Evaluate Maintenance and Durability:

Consider the maintenance requirements and durability of the variable pulley configuration. Assess factors such as the expected lifespan, maintenance intervals, and availability of spare parts.

7. Seek Expert Advice:

If necessary, consult with experts or manufacturers who specialize in variable pulley systems. They can provide valuable insights and recommendations based on their expertise and experience.

By carefully evaluating these factors, you can select the right variable pulley configuration that meets the specific requirements of your task or application. It is essential to consider the performance, functionality, and compatibility of the variable pulley system to ensure optimal results and long-term reliability.

How do variable pulleys contribute to the functionality of exercise equipment like treadmills?

Variable pulleys play a crucial role in the functionality of exercise equipment, such as treadmills. They enable users to adjust and control various aspects of their workout experience. Here are some ways in which variable pulleys contribute to the functionality of treadmills:

Speed Control:

Variable pulleys in treadmills allow users to control the speed at which the treadmill belt moves. By adjusting the position of the variable pulleys, users can increase or decrease the speed of the belt, providing flexibility to accommodate different workout intensities and fitness goals. Speed control is an essential feature that allows users to customize their workouts and gradually increase or decrease the intensity as needed.

Workout Programs:

Treadmills often come equipped with pre-programmed workout programs that simulate various terrains, such as hills or intervals. Variable pulleys are used in conjunction with these programs to automatically adjust the incline or resistance levels of the treadmill. By altering the position of the variable pulleys, the treadmill can mimic uphill climbs or simulate different levels of resistance, providing users with a more challenging and varied workout experience.

User Comfort:

Variable pulleys also contribute to user comfort on treadmills. By allowing users to adjust the speed and intensity of their workouts, variable pulleys ensure that individuals can exercise at a pace that suits their fitness level and preferences. Whether users prefer a leisurely stroll or an intense sprint, the ability to control the speed through variable pulleys provides a comfortable and personalized workout experience.

Safety Features:

Variable pulleys in treadmills are often equipped with safety features, such as emergency stop buttons or magnetic safety keys. These features are connected to the variable pulley system and can quickly halt the movement of the treadmill belt in case of an emergency or if the user loses balance. The variable pulley system plays a vital role in these safety mechanisms, ensuring immediate response and preventing accidents or injuries.

Smooth and Consistent Belt Movement:

Variable pulleys contribute to the smooth and consistent movement of the treadmill belt. The design and construction of the variable pulley system help maintain a steady and even belt motion, providing users with a stable running or walking surface. This ensures a comfortable and natural stride, reducing the risk of discomfort or strain during the workout.

In summary, variable pulleys are integral to the functionality of treadmills. They enable speed control, facilitate pre-programmed workout programs, enhance user comfort, incorporate safety features, and ensure smooth and consistent belt movement. These features combine to provide users with a versatile, customizable, and enjoyable workout experience on treadmills.

How does a variable pulley assist in changing the speed and power transmission?

A variable pulley, also known as a variable speed pulley or a variable drive pulley, plays a crucial role in changing the speed and power transmission in mechanical systems. Let’s explore how it accomplishes these functions:

1. Speed Adjustment:

A variable pulley allows for continuous speed adjustment by changing the effective diameter of the pulley system. When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases. This results in a larger belt or chain contact area and a higher speed ratio between the input and output shafts. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a smaller contact area and a lower speed ratio. By adjusting the position of the movable pulley half, the speed of the driven components can be precisely controlled without the need for manual gear changes or transmission adjustments.

2. Power Transmission:

A variable pulley transfers power from the input shaft to the output shaft through the belt or chain. By changing the speed ratio, the variable pulley adjusts the rotational speed of the output shaft relative to the input shaft. This allows for optimization of power transmission in mechanical systems. For example, in applications where high torque is required, the variable pulley can be adjusted to provide a lower speed ratio, resulting in increased torque at the output shaft. Conversely, when higher speeds are desired, the variable pulley can be adjusted to provide a higher speed ratio, sacrificing some torque in favor of increased rotational speed.

3. Smooth Transitions:

One of the advantages of a variable pulley is its ability to provide smooth transitions between different speed ratios. The actuation mechanism associated with the variable pulley allows for precise and controlled movement of the movable pulley half. This enables gradual adjustments in the effective diameter, ensuring seamless speed changes without sudden jolts or disturbances in power transmission.

4. Flexibility and Adaptability:

Variable pulleys offer flexibility and adaptability in mechanical systems. They can accommodate different load conditions, operational requirements, and variations in input power. By adjusting the position of the movable pulley half, the speed and power transmission characteristics can be tailored to suit specific needs, resulting in efficient and optimized performance.

Overall, a variable pulley assists in changing the speed and power transmission by providing continuous speed adjustment, optimizing power transfer, enabling smooth transitions, and offering flexibility in mechanical systems. Its ability to precisely control speed ratios without the need for manual gear changes makes it a valuable component in various applications, ranging from automotive systems and manufacturing machinery to exercise equipment and power transmission systems.

editor by CX

2023-10-23