Product Description

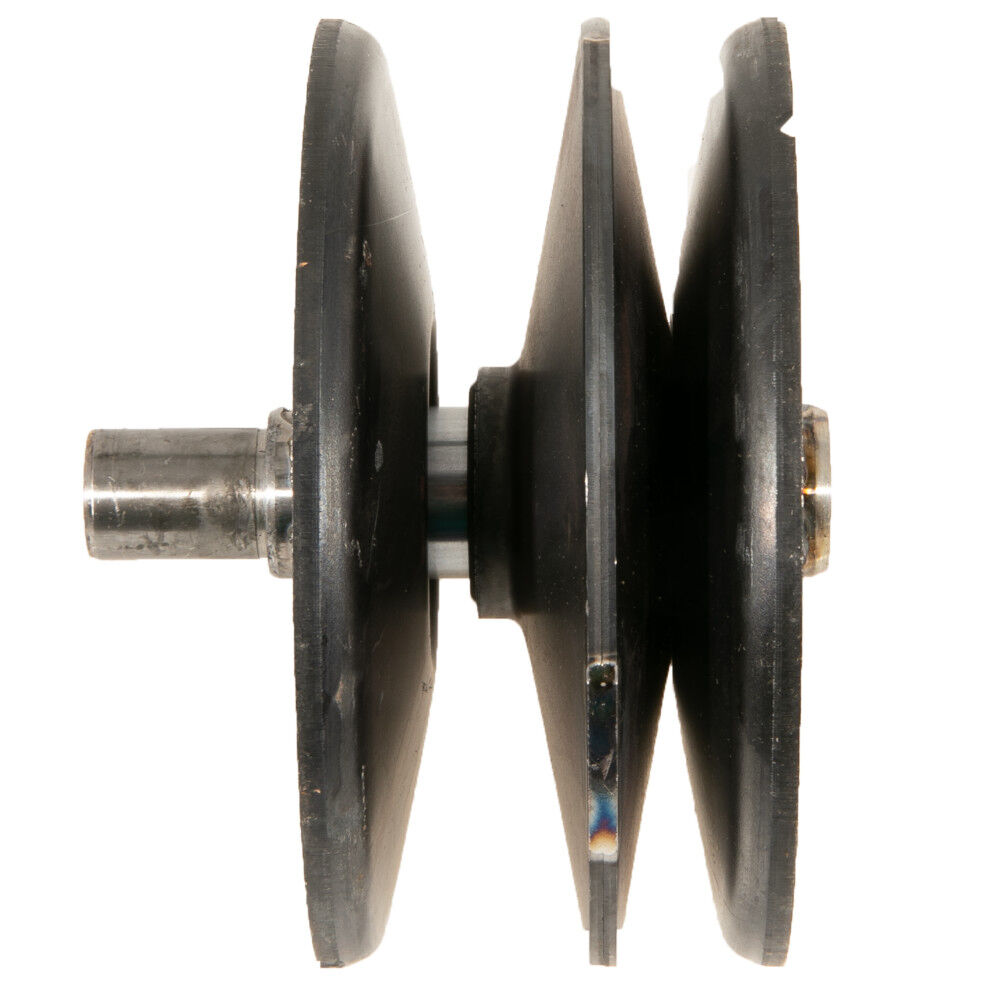

Adjustable Pulleys grooved belt wheel flat rope sheave aluminum motor bearing browning variable speed congress manufacturers gym equipment pulley metal

Product Description

A grooved pulley, also known as a sheave, is a type of pulley with 1 or more grooves or channels on its circumference. These grooves are designed to accommodate a belt or a rope, allowing for the transmission of power or the transfer of motion between rotating shafts.

The grooved pulley works in conjunction with a belt or rope that fits into the grooves. When the pulley rotates, the belt or rope also moves, transferring power or motion to other connected pulleys or machinery.

Key features and applications of grooved pulleys include:

-

Power Transmission: Grooved pulleys are commonly used in belt drive systems to transmit power from 1 rotating shaft to another. The grooves help to ensure a secure grip on the belt, preventing slipping and ensuring efficient power transmission.

-

Speed Adjustment: By using different-sized grooved pulleys and belts, the rotational speed of the driven shaft can be adjusted in relation to the driving shaft. This allows for speed variation and control in various applications.

-

Tensioning: Grooved pulleys are often used in combination with tensioning devices to maintain proper belt tension. This ensures optimal power transmission and prevents belt slippage.

-

Diverse Applications: Grooved pulleys find applications in a wide range of industries, including manufacturing, automotive, mining, agriculture, and CHINAMFG (heating, ventilation, and air conditioning) systems. They are utilized in equipment such as conveyor systems, fans, pumps, and generators.

-

Material and Design: Grooved pulleys are typically made of durable materials such as steel, aluminum, or cast iron, depending on the application requirements. They are designed with precision to ensure smooth belt operation and minimize friction.

-

Multiple Grooves: Some grooved pulleys have multiple grooves or channels, allowing for the use of multiple belts. This configuration enables power transmission to different shafts or accessories simultaneously.

It’s important to note that the specific design and characteristics of grooved pulleys can vary depending on the intended application and industry requirements.

Application of Plastic pulley

Plastic pulleys are used in a wide variety of applications, including:

- Conveyor belts: Plastic pulleys are commonly used in conveyor belts to transmit power from the motor to the belt.

- Fans: Plastic pulleys are used in fans to transmit power from the motor to the fan blades.

- Drills: Plastic pulleys are used in drills to transmit power from the motor to the drill bit.

- Winches: Plastic pulleys are used in winches to transmit power from the motor to the winch cable.

- Lifts: Plastic pulleys are used in lifts to transmit power from the motor to the lift cable.

- Sewing machines: Plastic pulleys are used in sewing machines to transmit power from the motor to the sewing needle.

- Other: Plastic pulleys are also used in various other applications, such as lawnmowers, go-karts, and bicycles.

Plastic pulleys are a versatile and reliable type of pulley that can be used in various applications. They are typically made of high-strength plastic, such as nylon or acetal, and they are available in various sizes and shapes. Plastic pulleys are also relatively inexpensive, making them a cost-effective option for many applications.

Here are some of the benefits of using plastic pulleys:

- They are lightweight and easy to transport.

- They are corrosion-resistant and can withstand a variety of harsh environments.

- They are non-magnetic and can be used in applications where magnetism is a concern.

- They are non-conductive and can be used in applications where electricity is a concern.

- They are relatively inexpensive and can be a cost-effective option for many applications.

If you are looking for a versatile, reliable, and cost-effective type of pulley, then a plastic pulley is a good option.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can variable pulleys be retrofitted into existing machinery for performance upgrades?

Yes, variable pulleys can often be retrofitted into existing machinery to provide performance upgrades. Retrofitting variable pulleys is a common practice to enhance the functionality, efficiency, and versatility of older or fixed-speed machines. Here are some key points to consider:

- Compatibility: Before retrofitting variable pulleys, it is important to assess the compatibility of the existing machinery. Consider factors such as the design of the machine, the power transmission system, and the available space for installing the variable pulleys. Consulting with a professional or the manufacturer of the variable pulleys can help determine the feasibility of retrofitting.

- Application suitability: Evaluate whether the addition of variable pulleys will be beneficial for the specific application of the machinery. Variable pulleys are particularly advantageous in situations where speed control, load adaptation, or precise adjustments are required. Assess the performance requirements of the machinery and determine if retrofitting variable pulleys will address any limitations or improve overall performance.

- Engineering considerations: Retrofitting variable pulleys may involve engineering modifications to the existing machinery. This can include adjusting or redesigning the power transmission system, modifying the mounting or support structures, or integrating additional components for the pulley adjustment mechanism. It is crucial to consult with engineering experts or professionals to ensure that the retrofitting process is carried out safely and effectively.

- Space and clearance: Check if there is sufficient space within the existing machinery to accommodate the variable pulleys. Consider the dimensions of the pulleys, the clearance required for belt movement, and any potential conflicts with other components or systems. Adequate space and clearance are essential for the proper installation and operation of the variable pulleys.

- System integration: Retrofitting variable pulleys may require integrating additional control mechanisms or systems into the existing machinery. This can include incorporating motor controllers, sensors, or automation components to enable precise speed adjustments and automation features. Proper integration ensures seamless operation and compatibility between the retrofitted variable pulleys and the rest of the machinery.

- Professional guidance: It is recommended to seek professional guidance or consult with experts in the field of retrofitting and machinery modifications. They can provide valuable insights, assess the technical aspects, and guide you through the process to ensure a successful retrofitting project.

Retrofitting variable pulleys into existing machinery can unlock new capabilities, improve performance, and extend the lifespan of the equipment. However, it is crucial to approach the retrofitting process with careful planning, engineering expertise, and consideration of the specific requirements and limitations of the machinery in question.

How does the adjustment of a variable pulley affect its performance?

The adjustment of a variable pulley has a significant impact on its performance and the overall performance of the system it is incorporated into. Let’s explore how the adjustment of a variable pulley affects its performance:

1. Speed Control:

By adjusting the position of the movable pulley half, the effective diameter of the pulley system is changed. This adjustment directly affects the speed control capability of the variable pulley. When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases, resulting in a higher speed ratio between the input and output shafts. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a lower speed ratio. Therefore, the adjustment of the variable pulley allows for precise speed control, enabling the system to operate at the desired speed for a given task.

2. Power Transmission:

The adjustment of a variable pulley also affects power transmission in the system. By changing the speed ratio, the variable pulley adjusts the rotational speed of the output shaft relative to the input shaft. This adjustment has an impact on the torque and power characteristics of the system. When the variable pulley is adjusted to provide a lower speed ratio, it increases the torque at the output shaft, allowing the system to handle higher loads or perform tasks requiring higher torque. Conversely, when the variable pulley is adjusted to provide a higher speed ratio, it sacrifices some torque in favor of increased rotational speed. This trade-off between torque and speed transmission allows for optimization of power transmission in different operating conditions.

3. Efficiency:

The adjustment of a variable pulley can also affect the efficiency of the system. By optimizing the speed ratio, the variable pulley helps the system operate at its most efficient point. In applications where energy efficiency is crucial, such as automotive systems or industrial machinery, adjusting the variable pulley to achieve the desired speed can minimize energy waste and improve overall system efficiency.

4. Belt Tension and Grip:

Proper adjustment of the variable pulley ensures optimal belt tension and grip. When the pulley halves are adjusted correctly, it ensures that the belt or chain is properly tensioned, preventing slippage and ensuring efficient power transmission. Improper adjustment can lead to belt slipping, reduced power transmission, and increased wear on the belt and pulley surfaces.

5. Smooth Transitions:

The adjustment mechanism associated with the variable pulley allows for smooth transitions between different speed ratios. Precise and controlled movement of the movable pulley half ensures gradual adjustments in the effective diameter, resulting in seamless speed changes without sudden jolts or disturbances in power transmission. This smooth transition capability enhances the overall performance and reliability of the system.

It’s important to note that the adjustment of a variable pulley should be done according to the manufacturer’s guidelines and specifications. Improper adjustment can result in suboptimal performance, increased wear, and reduced system efficiency. Regular maintenance and inspection of the variable pulley are also essential to ensure its continued performance and reliability.

In which industries and applications are variable pulleys commonly used?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, find extensive use in various industries and applications due to their ability to provide adjustable speed ratios. Here are some industries and applications where variable pulleys are commonly employed:

1. Automotive Industry:

Variable pulleys are widely used in automotive applications, particularly in continuously variable transmissions (CVTs). CVTs use variable pulleys to provide seamless speed adjustments, optimizing engine performance and fuel efficiency. They allow the engine to operate at its optimal speed for different driving conditions, resulting in smoother acceleration, improved fuel economy, and reduced emissions.

2. Manufacturing and Industrial Machinery:

In manufacturing and industrial settings, variable pulleys are utilized in various machinery and equipment. They are employed in conveyor systems, where they enable speed control to match the production requirements. Variable pulleys are also used in milling machines, lathes, and other machining equipment, allowing operators to adjust spindle speeds for different materials and cutting operations.

3. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems often incorporate variable pulleys in their fan and blower motors. By adjusting the pulley position, the speed of the fan or blower can be controlled to maintain the desired airflow and temperature regulation. This enables energy efficiency and precise climate control in residential, commercial, and industrial HVAC applications.

4. Agricultural Equipment:

Variable pulleys are utilized in various agricultural machinery, such as combine harvesters, tractors, and irrigation systems. They allow farmers to adjust the speed of different components, such as the harvesting mechanisms or water pumps, according to the specific requirements of the task or crop. Variable pulleys contribute to efficient agricultural operations and optimal utilization of resources.

5. Exercise Equipment:

In the fitness industry, variable pulleys are commonly found in exercise equipment like treadmills, elliptical trainers, and stationary bikes. These pulleys allow users to adjust the resistance and speed of the equipment, providing customizable workout intensity and accommodating different fitness levels.

6. Material Handling Systems:

Variable pulleys are utilized in material handling equipment, such as conveyors, lifts, and cranes. They enable precise speed control, allowing for efficient movement of goods and materials in warehouses, distribution centers, and manufacturing facilities.

7. Power Transmission Systems:

Variable pulleys play a crucial role in power transmission systems, where adjustable speed ratios are required. They are employed in applications like industrial pumps, compressors, and generators, allowing for flexible speed control and optimal performance.

These are just a few examples of the industries and applications where variable pulleys are commonly used. Their versatility and ability to provide adjustable speed ratios make them valuable components in numerous mechanical systems, contributing to improved efficiency, performance, and control.

editor by CX

2024-03-28