Product Description

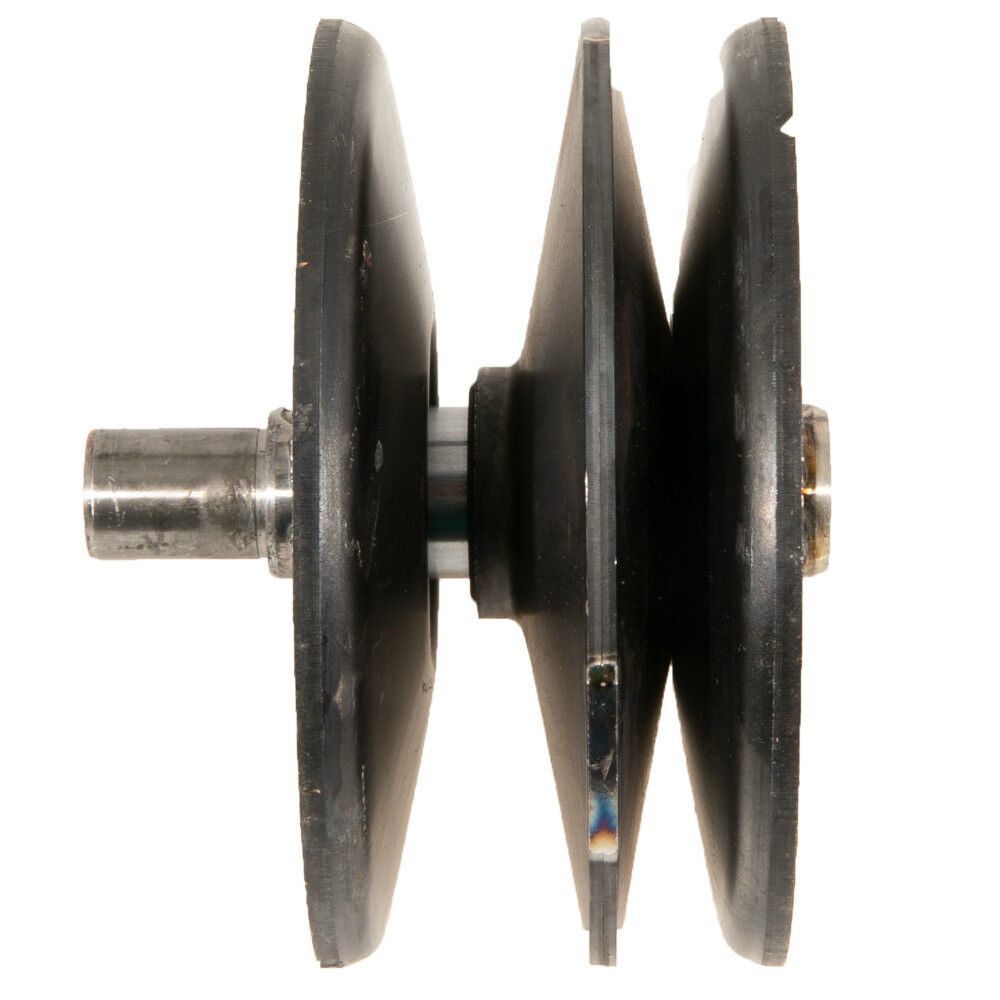

variable speed pulley ,V pulley, V belt pulley, V groove pulley, V groove belt pulley, taper lock pulley, taper lock V belt pulley, taper lock bushing pulley, taper lock pulleys / taper bore pulley, large V belt pulley, double V belt pulley, cast iron V belt pulley belt pulley, variable speed V belt pulleys, V belt pulley split pulley, cast iron V belt pulley

V belt pulley specifications:

1) European standard:

A) V-belt pulleys for taper bushings: SPZ, SPA, SPB, SPC; Up to 10 grooves

B) Adjustable speed V-belt pulleys and variable speed pulleys

C) Flat belt pulleys and conveyor belt pulleys

2) American standard:

A) Sheaves for taper bushings: 3V, 5V, 8V

B) Sheaves for QD bushings: 3V, 5V, 8V

C) Sheaves for split taper bushings: 3V, 5V, 8V

D) Sheaves for 3L, 4L or A, and 5L or B belts: AK, AKH, 2AK, 2AKH, BK, BKH, 2BK, 2BKH, 3BK

E) Adjustable sheaves: Poly V-pulley, multi-pitch H, L, J, K and M

3) Bore: Pilot bore, finished bore, taper bore, bore for QD bushing

4) Surface finish: Paint, phosphating, zinc plated

5) Material: Cast iron, ductile iron, nylon, aluminum

6) Made according to drawings and/or samples, OEM inquiries welcomed

|

|

Specification: |

| 1 | Made of superior cast iron; Pulley type: V Pulley; |

| 2 | Good hardness and strength. Anticorrosive capability; |

| 3 | SPA, SPB, SPC, SPZ, AK, AKH, 2AK, 2AKH, BK, BKH,2BK, 2BKH, 3BK and non-standard series; |

| 4 | All the products would be done by precise machining and power painting to get smooth surface; |

| 5 | Every product would be tested repeatedly and carefully before the shipment; |

| 6 | Safe package to protect products during the shipment; |

| Advantages: | |

| 1 | The strong technology group as well as the advanced equipment; |

| 2 | More than 20 years experience; |

| 3 | The Products have got good comments in the world market; |

| 4 | OEM service and special design service be accepted; |

| 5 | ISO9001-2000 Certified. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Cast Iron |

|---|---|

| Application: | Industry |

| Hardness: | Hardened |

| Manipulate Way: | Forced Manipulation |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Customization: |

Available

| Customized Request |

|---|

Can variable pulleys be retrofitted into existing machinery for performance upgrades?

Yes, variable pulleys can often be retrofitted into existing machinery to provide performance upgrades. Retrofitting variable pulleys is a common practice to enhance the functionality, efficiency, and versatility of older or fixed-speed machines. Here are some key points to consider:

- Compatibility: Before retrofitting variable pulleys, it is important to assess the compatibility of the existing machinery. Consider factors such as the design of the machine, the power transmission system, and the available space for installing the variable pulleys. Consulting with a professional or the manufacturer of the variable pulleys can help determine the feasibility of retrofitting.

- Application suitability: Evaluate whether the addition of variable pulleys will be beneficial for the specific application of the machinery. Variable pulleys are particularly advantageous in situations where speed control, load adaptation, or precise adjustments are required. Assess the performance requirements of the machinery and determine if retrofitting variable pulleys will address any limitations or improve overall performance.

- Engineering considerations: Retrofitting variable pulleys may involve engineering modifications to the existing machinery. This can include adjusting or redesigning the power transmission system, modifying the mounting or support structures, or integrating additional components for the pulley adjustment mechanism. It is crucial to consult with engineering experts or professionals to ensure that the retrofitting process is carried out safely and effectively.

- Space and clearance: Check if there is sufficient space within the existing machinery to accommodate the variable pulleys. Consider the dimensions of the pulleys, the clearance required for belt movement, and any potential conflicts with other components or systems. Adequate space and clearance are essential for the proper installation and operation of the variable pulleys.

- System integration: Retrofitting variable pulleys may require integrating additional control mechanisms or systems into the existing machinery. This can include incorporating motor controllers, sensors, or automation components to enable precise speed adjustments and automation features. Proper integration ensures seamless operation and compatibility between the retrofitted variable pulleys and the rest of the machinery.

- Professional guidance: It is recommended to seek professional guidance or consult with experts in the field of retrofitting and machinery modifications. They can provide valuable insights, assess the technical aspects, and guide you through the process to ensure a successful retrofitting project.

Retrofitting variable pulleys into existing machinery can unlock new capabilities, improve performance, and extend the lifespan of the equipment. However, it is crucial to approach the retrofitting process with careful planning, engineering expertise, and consideration of the specific requirements and limitations of the machinery in question.

How do variable pulleys contribute to the functionality of exercise equipment like treadmills?

Variable pulleys play a crucial role in the functionality of exercise equipment, such as treadmills. They enable users to adjust and control various aspects of their workout experience. Here are some ways in which variable pulleys contribute to the functionality of treadmills:

Speed Control:

Variable pulleys in treadmills allow users to control the speed at which the treadmill belt moves. By adjusting the position of the variable pulleys, users can increase or decrease the speed of the belt, providing flexibility to accommodate different workout intensities and fitness goals. Speed control is an essential feature that allows users to customize their workouts and gradually increase or decrease the intensity as needed.

Workout Programs:

Treadmills often come equipped with pre-programmed workout programs that simulate various terrains, such as hills or intervals. Variable pulleys are used in conjunction with these programs to automatically adjust the incline or resistance levels of the treadmill. By altering the position of the variable pulleys, the treadmill can mimic uphill climbs or simulate different levels of resistance, providing users with a more challenging and varied workout experience.

User Comfort:

Variable pulleys also contribute to user comfort on treadmills. By allowing users to adjust the speed and intensity of their workouts, variable pulleys ensure that individuals can exercise at a pace that suits their fitness level and preferences. Whether users prefer a leisurely stroll or an intense sprint, the ability to control the speed through variable pulleys provides a comfortable and personalized workout experience.

Safety Features:

Variable pulleys in treadmills are often equipped with safety features, such as emergency stop buttons or magnetic safety keys. These features are connected to the variable pulley system and can quickly halt the movement of the treadmill belt in case of an emergency or if the user loses balance. The variable pulley system plays a vital role in these safety mechanisms, ensuring immediate response and preventing accidents or injuries.

Smooth and Consistent Belt Movement:

Variable pulleys contribute to the smooth and consistent movement of the treadmill belt. The design and construction of the variable pulley system help maintain a steady and even belt motion, providing users with a stable running or walking surface. This ensures a comfortable and natural stride, reducing the risk of discomfort or strain during the workout.

In summary, variable pulleys are integral to the functionality of treadmills. They enable speed control, facilitate pre-programmed workout programs, enhance user comfort, incorporate safety features, and ensure smooth and consistent belt movement. These features combine to provide users with a versatile, customizable, and enjoyable workout experience on treadmills.

What are the advantages of using variable pulleys in various systems?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, offer several advantages when incorporated into various mechanical systems. Here are some key advantages of using variable pulleys:

1. Adjustable Speed Ratios:

One of the primary advantages of variable pulleys is their ability to provide adjustable speed ratios. By changing the position of the movable pulley half, the effective diameter of the pulley system can be altered, resulting in different speed ratios between the input and output shafts. This feature allows for precise and continuous speed adjustment without the need for manual gear changes or transmission adjustments. It enables systems to operate at optimal speeds for different conditions and tasks, enhancing efficiency and performance.

2. Smooth and Seamless Transitions:

Variable pulleys facilitate smooth and seamless transitions between different speed ratios. The actuation mechanism associated with the variable pulley allows for controlled movement of the movable pulley half, ensuring gradual adjustments in the effective diameter. This results in smooth speed changes without sudden jolts or disturbances in power transmission, contributing to overall system reliability and user comfort.

3. Energy Efficiency:

By providing adjustable speed control, variable pulleys contribute to energy efficiency in various systems. They allow the system to operate at the optimal speed for a given task, minimizing energy waste and reducing unnecessary power consumption. For example, in automotive applications, variable pulleys in continuously variable transmissions (CVTs) enable the engine to operate at its most efficient speed, resulting in improved fuel economy and reduced emissions.

4. Flexibility and Adaptability:

Variable pulleys offer flexibility and adaptability in mechanical systems. They can accommodate different load conditions, operational requirements, and variations in input power. By adjusting the position of the movable pulley half, the speed and power transmission characteristics can be tailored to suit specific needs, allowing for optimized performance in diverse applications.

5. Cost-Effective Solution:

Variable pulleys can provide a cost-effective solution compared to other speed control mechanisms. Their simplicity in design and operation often results in lower manufacturing, installation, and maintenance costs. Additionally, the ability to adjust speed ratios without requiring complex gear systems or transmission components can reduce overall system complexity and associated costs.

6. Precise Speed Control:

Variable pulleys offer precise speed control in mechanical systems. The fine adjustments in the effective diameter allow for accurate speed setting, enabling systems to meet specific speed requirements with high precision. This is particularly advantageous in applications where precise speed synchronization, timing, or regulation is critical.

7. Reduced Mechanical Stress:

The ability to adjust speed ratios using variable pulleys can help reduce mechanical stress on system components. By optimizing the speed and torque characteristics, variable pulleys can minimize undue strain on belts, bearings, gears, and other transmission elements. This can result in extended component life, reduced maintenance, and improved overall system reliability.

These advantages make variable pulleys a valuable component in various systems, including automotive transmissions, manufacturing machinery, HVAC systems, exercise equipment, and power transmission systems. Their ability to provide adjustable speed ratios, smooth transitions, energy efficiency, and precise control contributes to enhanced performance, flexibility, and cost-effectiveness.

editor by CX

2024-04-11