Product Description

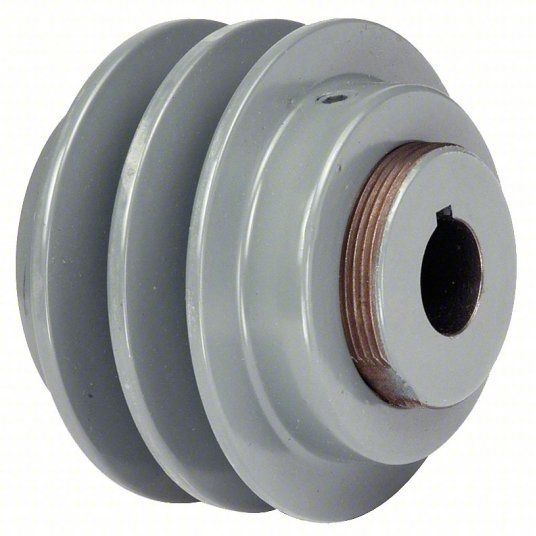

v belt pulley taper lock Adjustable Pulleys for taper bushes with CHINAMFG hub grooved double 6 inch step variable speed variable congress small aluminum sheave

What is v belt pulley?

A V-belt pulley is a type of pulley that is used with V-belts. V-belts are a type of belt that has a trapezoidal cross-section. This cross-section allows the belt to grip the pulley more effectively, which results in more efficient power transmission.

V-belt pulleys are typically made of metal or plastic. They have a grooved rim that the V-belt wraps around. The pulley is attached to a shaft, and the belt is attached to another shaft. When the shaft turns, the pulley turns, and the belt turns the other shaft.

V-belt pulleys are used in a variety of applications, including:

- Automotive engines: V-belt pulleys are used in automotive engines to transmit power from the crankshaft to the accessories, such as the alternator, water pump, and power steering pump.

- Air conditioning: V-belt pulleys are used in air conditioning systems to transmit power from the engine to the compressor.

- Conveyor belts: V-belt pulleys are used in conveyor belts to transmit power from the motor to the belt.

- Other machines: V-belt pulleys are also used in other machines, such as generators and pumps.

V-belt pulleys are a reliable and efficient way to transmit power. They are easy to install and maintain, and they are available in a variety of sizes and styles.

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What are some real-world examples of variable pulley applications in various industries?

Variable pulleys, also known as variable speed pulleys or adjustable pulleys, have diverse applications across various industries. Here are some real-world examples of how variable pulleys are used:

1. Automotive Industry:

In the automotive industry, variable pulleys are commonly used in continuously variable transmissions (CVTs). CVTs utilize toroidal or continuously variable pulleys to provide seamless and efficient variation of the gear ratio in vehicles. This allows for optimal engine performance across different driving conditions, resulting in improved fuel efficiency and smoother acceleration.

2. Industrial Machinery:

Variable pulleys find extensive applications in industrial machinery, where adjustable speed and power transmission are crucial. They are used in machinery such as milling machines, lathes, drill presses, and conveyor systems. By adjusting the position of the belt or changing the effective diameter of the pulley, variable pulleys enable operators to control the speed and torque output, facilitating versatile and efficient operation.

3. Exercise Equipment:

Treadmills, elliptical trainers, and stationary bikes are examples of exercise equipment that utilize variable pulleys. These pulleys allow users to control the speed and intensity of their workouts, providing a customizable and challenging exercise experience. By adjusting the position of the variable pulleys, users can increase or decrease the resistance, simulate different terrains, or vary the workout programs, enhancing the effectiveness of the workout.

4. Textile Industry:

In the textile industry, variable pulleys are used in various textile machines such as spinning machines, weaving looms, and knitting machines. These pulleys enable operators to adjust the speed and tension of the belts and threads, ensuring precise control over the production process and optimizing the quality of the textile products.

5. Power Transmission Systems:

Variable pulleys play a critical role in power transmission systems, where the speed and torque requirements can vary. They are used in applications such as conveyors, pumps, compressors, and fans, allowing for efficient power transmission and the ability to adjust the speed according to the specific needs of the system.

6. Woodworking Industry:

Woodworking equipment, such as table saws, band saws, and planers, often utilize variable pulleys. These pulleys enable operators to adjust the cutting speed and optimize the performance based on the type of wood and the desired outcome. By changing the position of the belt or adjusting the effective diameter of the pulley, woodworkers can achieve precise control over their cutting operations.

These examples demonstrate the widespread use of variable pulleys in various industries. Their ability to provide adjustable speed, torque, and power transmission makes them valuable components in machinery and equipment, enabling flexibility, efficiency, and improved performance.

What is the significance of proper alignment and tensioning in variable pulley systems?

Proper alignment and tensioning play a crucial role in the performance, efficiency, and longevity of variable pulley systems. The significance of these factors can be understood as follows:

Alignment:

Proper alignment of variable pulleys ensures that the input and output shafts of the machinery are precisely positioned in relation to each other. Here are some key points highlighting the significance of alignment:

- Efficient Power Transmission: Accurate alignment allows for optimal power transmission from the input to the output shaft. Misalignment can cause increased friction, energy loss, and reduced efficiency, leading to unnecessary wear and tear of the pulleys and belts.

- Reduced Vibration: Proper alignment minimizes vibration in the pulley system. Vibrations can not only affect the smooth operation of machinery but also contribute to premature wear of components, increased noise levels, and decreased overall performance.

- Prevention of Premature Wear: Misalignment can result in uneven belt wear, leading to premature belt failure. By ensuring proper alignment, the load is evenly distributed across the belt, reducing wear and extending the lifespan of both the belt and the pulleys.

- Protection of Components: Correct alignment helps protect the pulleys, belts, bearings, and other components of the variable pulley system from excessive stress and strain. It prevents unnecessary friction, heat generation, and component fatigue, thereby reducing the likelihood of breakdowns and costly repairs.

Tensioning:

Proper tensioning of the belts or chains used with variable pulleys is equally important. Here are some reasons highlighting the significance of tensioning:

- Optimal Grip and Power Transmission: Proper belt tension ensures that the belt maintains sufficient grip on the pulleys, facilitating efficient power transmission. Insufficient tension can cause slippage, resulting in decreased performance, loss of torque, and potential damage to the pulleys and belts.

- Prevention of Belt Damage: Over-tensioning or under-tensioning the belt can lead to excessive stress on the belt material, causing stretching, cracking, or premature wear. By maintaining the correct tension, the belt operates within its design limits, minimizing the risk of belt failure.

- Reduced Vibrations and Noise: Proper tensioning helps minimize belt vibrations, reducing noise levels and providing a smoother and quieter operation of the variable pulley system.

- Extended Belt and Pulley Lifespan: Optimal tensioning reduces the wear and tear on both the belt and the pulleys. It helps maintain the integrity of the belt material and prevents excessive forces on the pulley components, contributing to longer lifespans for these critical elements.

In summary, proper alignment and tensioning are essential for the reliable and efficient operation of variable pulley systems. Accurate alignment ensures efficient power transmission, reduced vibration, and prevention of premature wear, while proper tensioning facilitates optimal grip, power transmission, and extends the lifespan of belts and pulleys. By paying attention to these factors, operators can maximize the performance and longevity of their variable pulley systems.

What types of belts are typically employed with variable pulleys?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, are compatible with various types of belts. The choice of belt depends on factors such as the specific application, power transmission requirements, and environmental conditions. Here are some types of belts commonly employed with variable pulleys:

1. V-Belts:

V-belts are one of the most common types of belts used with variable pulleys. They have a trapezoidal cross-section and are designed to fit into V-shaped grooves on the pulley halves. V-belts are known for their high friction grip, which allows for efficient power transmission. They can handle moderate to high-speed ratios and are suitable for applications requiring reliable power transfer.

2. Flat Belts:

Flat belts have a rectangular cross-section and are widely used with variable pulleys. They offer flexibility and are capable of transmitting high power loads. Flat belts typically have fabric or rubber coatings on both sides to enhance grip and prevent slippage. They are commonly used in applications where a wide speed range and high torque transmission are required.

3. Timing Belts:

Timing belts, also known as synchronous belts, are toothed belts that mesh with corresponding teeth on the pulley halves. They provide precise power transmission and are often used in applications where accurate timing and synchronization are critical. Timing belts are commonly employed in automotive engines, robotics, and other precision machinery.

4. Poly-V Belts:

Poly-V belts, also called multi-rib belts, have multiple V-shaped ribs on the inner surface. They are designed to fit into corresponding grooves on the pulleys. Poly-V belts offer high power transmission capabilities and are suitable for applications that require compact designs and high-speed ratios. They are commonly used in automotive accessory drives, such as alternator and power steering systems.

5. Round Belts:

Round belts, as the name suggests, have a circular cross-section and are commonly made of rubber or urethane materials. They provide flexibility and are often used in applications that require minimal vibration and noise. Round belts are suitable for light to moderate power transmission and are commonly used in applications such as office equipment, textile machinery, and small appliances.

It’s important to note that the selection of the appropriate belt for a variable pulley should consider factors such as load requirements, speed range, temperature constraints, and environmental conditions. Consulting the manufacturer’s specifications and recommendations can help ensure the optimal belt choice for a given application.

editor by CX

2023-09-30