Product Description

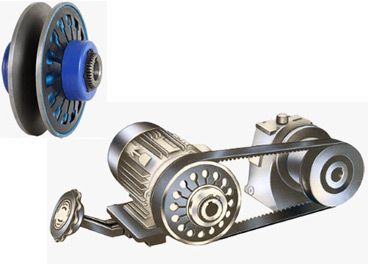

Mighty High Precise Variable Speed Timing Pulleys 3M/5M/8M/Gt2 20 Teeth sheave pulleys

| Plain bore | MXL, XL, L, H; T2.5, T5, T10; AT5, AT10; HTD 3M, 5M, 8M, 14M |

| Taper bore | XL, L, H, XH; HTD 5M, 8M,14M |

| Material | Aluminium, Cast Iron, Steel |

| Surface Treatment | Black, Phosphate, Zinc Plating, Hard anodized, Nitriding, Dichromate |

| Teeth Number | from 9 to 216 |

| Equipment | Hobbing machine,Drilling machine,CNC machine,Milling machine,Gear shaper,Grinder etc |

| Tolerance | Per customer’s requirement |

| Service | OEM & ODM |

Use:

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric power, telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3. Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket excavator bucket, wheel excavators .

5. Crane:Tower crane, gantry crande, bridge crane.

6. Others:Various elevators, coal plough, ball mill, crusher, recreation machine.

7. Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling:including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling, Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack

8. Other customized Machining Parts according to drawings (OEM).

More Advantages:

1. More competitive prices,

2. Shorter delivery date: 35 days.

3. We are the professional manufacturer in the field of Power Trans. Parts,specially for Timing Pulleys.

4. Produce standard and non-standard

5. Strict QC Management:ISO9001:2008,our engineer,Mr.Wang has specialized in the prodcution for over 20 years.

Packaging & Shipping:

All the products can be packed in cartons,or,you can choose the pallet packing.

MADE IN CHINA can be pressed on wooden cases.Land,air,sea transportation are available.UPS,DHL,TNT,

FedEx and EMS are all supported.

Company:

Factory View:

Exhibition:

FAQ:

1. MOQ

A: Generally, 1 pc for standard parts; contact for nonstandard parts.

2. Delivery Time

A: In stock: within 5 working days. Out of stock: depends on your order quantity.

3. How To Select

A: part number or drawing, catalogue. If no, you can send us your sample, so we can make the drawing and sample accordingly.

4: What is the Warranty for your products?

A:Normally our warranty is 1 year.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Htd Mxl XL T at H L |

| Material: | Steel, Aluminum, Cast Iron |

| Surface Treatment: | Black Oxide, Anodized, Zinced, etc. |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Teeth Number: | 22t-192t |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with variable pulleys?

When working with variable pulleys, it is important to keep several safety considerations in mind to ensure the well-being of individuals and prevent accidents. Here are some key safety considerations:

- Proper training: Only trained and authorized personnel should operate or work with variable pulleys. They should have a thorough understanding of the equipment, its functions, and the associated hazards. Training should cover topics such as proper usage, maintenance, and emergency procedures.

- Equipment inspection: Before using variable pulleys, it is crucial to inspect them for any signs of damage or wear. Check for issues such as frayed cables, loose bolts, or misalignment. If any defects are found, the pulleys should be taken out of service until repairs or replacements are made.

- Personal protective equipment (PPE): Workers should wear appropriate PPE, such as safety goggles, gloves, and protective clothing, to prevent injuries from flying debris, pinch points, or accidental contact with moving parts.

- Secure footing: Ensure that the work area around the variable pulleys is clean, well-lit, and free from any obstructions. Maintain good footing and position yourself in a stable manner to avoid slips, trips, and falls.

- Guarding: Install appropriate guards or barriers around the pulleys to prevent accidental contact with moving parts. This can include safety covers or enclosures that restrict access to the pulleys during operation.

- Lockout/tagout: Implement lockout/tagout procedures to control hazardous energy sources when performing maintenance or repairs on variable pulleys. This ensures that the equipment is properly shut down, isolated, and cannot be unintentionally started.

- Weight capacity: Always adhere to the weight capacity limits specified by the manufacturer. Overloading the pulleys can lead to equipment failure, loss of control, or structural damage.

- Proper use: Follow the manufacturer’s instructions and guidelines for the appropriate use of variable pulleys. Avoid using them for tasks or loads they are not designed for, as this can pose safety risks.

- Regular maintenance: Perform routine inspections, cleaning, and maintenance of the variable pulleys as recommended by the manufacturer. This helps identify potential issues early on and ensures the equipment operates safely and efficiently.

- Emergency preparedness: Have emergency procedures in place, including knowledge of emergency stops, shutdown procedures, and how to respond to accidents or malfunctions involving variable pulleys. Workers should be aware of evacuation routes and have access to communication devices for summoning help if needed.

What role do variable pulleys play in achieving variable speed control in machinery?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, play a crucial role in achieving variable speed control in machinery. They provide a means to adjust the speed ratio between the input and output shafts, allowing for precise control of rotational speed. Here’s how variable pulleys enable variable speed control:

1. Speed Adjustment:

Variable pulleys consist of two pulley halves: a fixed pulley half and a movable pulley half. The movable pulley half can be adjusted along the axis of the shaft, changing its effective diameter. By altering the position of the movable pulley half, the speed ratio between the input and output shafts can be modified. When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases, resulting in a higher speed ratio. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a lower speed ratio. This adjustability allows for fine-tuning of the speed control in machinery.

2. Continuous Speed Variation:

Unlike fixed-speed pulleys or gear systems with discrete speed settings, variable pulleys offer continuous speed variation. The adjustment mechanism associated with variable pulleys enables smooth and seamless transitions between different speed ratios. By precisely positioning the movable pulley half, the desired speed can be achieved without the need for manual gear changes or transmission adjustments. This continuous speed variation capability allows machinery to operate at optimal speeds for different tasks or operating conditions.

3. Energy Efficiency:

Variable pulleys contribute to energy efficiency in machinery. By providing adjustable speed control, they allow the system to operate at the most efficient speed for a given task. This optimization minimizes energy waste and reduces unnecessary power consumption. For example, in applications such as HVAC systems or industrial machinery, variable pulleys enable the motor or engine to operate at the most efficient speed, resulting in improved energy efficiency and reduced operating costs.

4. Load Adaptation:

Variable pulleys facilitate load adaptation in machinery. By adjusting the speed ratio, the torque and power characteristics of the system can be optimized to match the specific load requirements. When higher torque is needed, the variable pulley can be adjusted to provide a lower speed ratio, allowing the system to handle heavier loads. Conversely, when speed is a priority, the variable pulley can be adjusted to provide a higher speed ratio, sacrificing some torque in favor of increased rotational speed. This load adaptation capability allows machinery to effectively handle varying load conditions.

5. Control Precision:

Variable pulleys offer precise speed control, enabling machinery to meet specific speed requirements with high precision. The fine adjustments in the effective diameter allow for accurate and controlled speed setting. This level of control precision is particularly advantageous in applications where precise speed synchronization, timing, or regulation is critical, such as in robotics, conveyor systems, or automated manufacturing processes.

By providing adjustable speed control, continuous speed variation, energy efficiency, load adaptation, and control precision, variable pulleys play a vital role in achieving variable speed control in machinery. Their flexibility and ability to fine-tune speed ratios contribute to improved performance, productivity, and efficiency in various industrial and mechanical applications.

What are the advantages of using variable pulleys in various systems?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, offer several advantages when incorporated into various mechanical systems. Here are some key advantages of using variable pulleys:

1. Adjustable Speed Ratios:

One of the primary advantages of variable pulleys is their ability to provide adjustable speed ratios. By changing the position of the movable pulley half, the effective diameter of the pulley system can be altered, resulting in different speed ratios between the input and output shafts. This feature allows for precise and continuous speed adjustment without the need for manual gear changes or transmission adjustments. It enables systems to operate at optimal speeds for different conditions and tasks, enhancing efficiency and performance.

2. Smooth and Seamless Transitions:

Variable pulleys facilitate smooth and seamless transitions between different speed ratios. The actuation mechanism associated with the variable pulley allows for controlled movement of the movable pulley half, ensuring gradual adjustments in the effective diameter. This results in smooth speed changes without sudden jolts or disturbances in power transmission, contributing to overall system reliability and user comfort.

3. Energy Efficiency:

By providing adjustable speed control, variable pulleys contribute to energy efficiency in various systems. They allow the system to operate at the optimal speed for a given task, minimizing energy waste and reducing unnecessary power consumption. For example, in automotive applications, variable pulleys in continuously variable transmissions (CVTs) enable the engine to operate at its most efficient speed, resulting in improved fuel economy and reduced emissions.

4. Flexibility and Adaptability:

Variable pulleys offer flexibility and adaptability in mechanical systems. They can accommodate different load conditions, operational requirements, and variations in input power. By adjusting the position of the movable pulley half, the speed and power transmission characteristics can be tailored to suit specific needs, allowing for optimized performance in diverse applications.

5. Cost-Effective Solution:

Variable pulleys can provide a cost-effective solution compared to other speed control mechanisms. Their simplicity in design and operation often results in lower manufacturing, installation, and maintenance costs. Additionally, the ability to adjust speed ratios without requiring complex gear systems or transmission components can reduce overall system complexity and associated costs.

6. Precise Speed Control:

Variable pulleys offer precise speed control in mechanical systems. The fine adjustments in the effective diameter allow for accurate speed setting, enabling systems to meet specific speed requirements with high precision. This is particularly advantageous in applications where precise speed synchronization, timing, or regulation is critical.

7. Reduced Mechanical Stress:

The ability to adjust speed ratios using variable pulleys can help reduce mechanical stress on system components. By optimizing the speed and torque characteristics, variable pulleys can minimize undue strain on belts, bearings, gears, and other transmission elements. This can result in extended component life, reduced maintenance, and improved overall system reliability.

These advantages make variable pulleys a valuable component in various systems, including automotive transmissions, manufacturing machinery, HVAC systems, exercise equipment, and power transmission systems. Their ability to provide adjustable speed ratios, smooth transitions, energy efficiency, and precise control contributes to enhanced performance, flexibility, and cost-effectiveness.

editor by CX

2023-09-25