Product Description

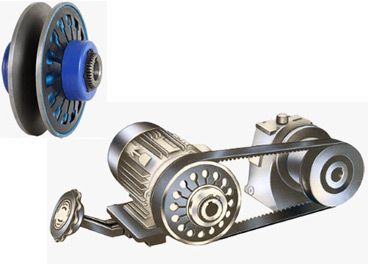

SC Transmission Adjustable V-belt pulley

Variable Speed Pulley VAR Pulley Series

Variable speed V-Pulleys offer a cost-effective solution for varying the speed of a driven shaft without the expense of variable speed motors. The groove/s in the pulleys can be opened and closed which in turn alters the PCD of the pulley and therefor the driven shafts speed. The speed variation is technically limitless, although each model of pulley has a maximum and minimum diameter.

Variable speed V-Pulleys are available as standard for the SPZ, SPA and CHINAMFG V-Belts. They come with either single or double grooves along with the option for pilot or taper bores.

Product Description

Features

• All pulleys are produced from cast iron or steel and have a phosphated finish for protection

• V, Multiple Groove and PV pulleys are balanced to Q6.3 or better allowing them to run at peripheral (rim) speeds up to 40 m/s

V Belt Pulleys

• Can accommodate both wedge and classical belts.

• Dual duty design complying with ISO 4183.

• Manufactured from GG25 high grade cast iron.

• Available in taper bore. Pilot and QD bush bores can be produced on enquiry.

• A wide range of non-standard styles and sizes up to a diameter of 2400 mm can be produced.

Product Parameters

Adjustable V-belt pulley Variable Speed Pulley VAR Pulley Series

Company Profile

FAQ

Shipping

| Pulley Sizes: | Var |

|---|---|

| Manufacturing Process: | Casting |

| Material: | Cast Iron |

| Surface Treatment: | Phosphated Finish |

| Transport Package: | Plywood Case |

| Trademark: | SC Transmission or OEM |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do variable pulleys contribute to energy efficiency in industrial processes?

Variable pulleys play a significant role in enhancing energy efficiency in industrial processes. By providing precise control over speed and load adaptation, variable pulleys offer several benefits that contribute to reducing energy consumption and optimizing overall efficiency. Here are some ways in which variable pulleys contribute to energy efficiency:

- Optimized power transmission: Variable pulleys efficiently transmit power from the input shaft to the output shaft, minimizing energy losses. By adjusting the position of the pulley’s movable flanges, the effective diameter of the pulley changes, allowing for optimal power transmission based on the load requirements. This efficient power transmission reduces energy waste and ensures that the machinery operates at its optimum power efficiency.

- Speed control: One of the primary advantages of variable pulleys is their ability to control the speed of machinery. By adjusting the pulley’s effective diameter and changing the speed ratio between the input and output shafts, operators can match the speed of the machinery to the specific requirements of the process. This prevents over-speeding or under-speeding of the equipment, resulting in energy savings by avoiding unnecessary power consumption.

- Load adaptation: Variable pulleys allow machinery to adapt to varying load conditions. By adjusting the pulley’s setting, operators can vary the torque and speed output of the system to match the requirements of the load. This load adaptation ensures that the machinery operates at the most efficient operating point, minimizing energy waste and improving overall energy efficiency.

- Efficient process control: Variable pulleys enable precise adjustments in speed and torque, providing better control over industrial processes. This control allows operators to optimize the process parameters based on energy efficiency considerations. For example, in applications where a slower speed can achieve the desired outcome, operators can adjust the pulley settings accordingly, reducing energy consumption while maintaining process effectiveness.

- Reduced mechanical losses: Variable pulleys help minimize mechanical losses in industrial processes. By avoiding fixed-speed operation and using variable speed control, the machinery can avoid unnecessary friction and wear associated with running at higher speeds than required. This reduction in mechanical losses contributes to energy efficiency and can extend the lifespan of the equipment.

- Energy recovery: In certain industrial processes, variable pulleys can enable energy recovery systems. For example, in applications where the machinery produces excess energy during certain phases, variable pulleys can be adjusted to recover and utilize that energy elsewhere in the process. By capturing and reusing this energy, overall energy consumption can be reduced, leading to improved energy efficiency.

The precise control and load adaptation capabilities of variable pulleys make them valuable tools in optimizing energy efficiency in industrial processes. By reducing energy waste, enhancing process control, and minimizing mechanical losses, variable pulleys contribute to significant energy savings and promote sustainable industrial operations.

What role do variable pulleys play in achieving variable speed control in machinery?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, play a crucial role in achieving variable speed control in machinery. They provide a means to adjust the speed ratio between the input and output shafts, allowing for precise control of rotational speed. Here’s how variable pulleys enable variable speed control:

1. Speed Adjustment:

Variable pulleys consist of two pulley halves: a fixed pulley half and a movable pulley half. The movable pulley half can be adjusted along the axis of the shaft, changing its effective diameter. By altering the position of the movable pulley half, the speed ratio between the input and output shafts can be modified. When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases, resulting in a higher speed ratio. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a lower speed ratio. This adjustability allows for fine-tuning of the speed control in machinery.

2. Continuous Speed Variation:

Unlike fixed-speed pulleys or gear systems with discrete speed settings, variable pulleys offer continuous speed variation. The adjustment mechanism associated with variable pulleys enables smooth and seamless transitions between different speed ratios. By precisely positioning the movable pulley half, the desired speed can be achieved without the need for manual gear changes or transmission adjustments. This continuous speed variation capability allows machinery to operate at optimal speeds for different tasks or operating conditions.

3. Energy Efficiency:

Variable pulleys contribute to energy efficiency in machinery. By providing adjustable speed control, they allow the system to operate at the most efficient speed for a given task. This optimization minimizes energy waste and reduces unnecessary power consumption. For example, in applications such as HVAC systems or industrial machinery, variable pulleys enable the motor or engine to operate at the most efficient speed, resulting in improved energy efficiency and reduced operating costs.

4. Load Adaptation:

Variable pulleys facilitate load adaptation in machinery. By adjusting the speed ratio, the torque and power characteristics of the system can be optimized to match the specific load requirements. When higher torque is needed, the variable pulley can be adjusted to provide a lower speed ratio, allowing the system to handle heavier loads. Conversely, when speed is a priority, the variable pulley can be adjusted to provide a higher speed ratio, sacrificing some torque in favor of increased rotational speed. This load adaptation capability allows machinery to effectively handle varying load conditions.

5. Control Precision:

Variable pulleys offer precise speed control, enabling machinery to meet specific speed requirements with high precision. The fine adjustments in the effective diameter allow for accurate and controlled speed setting. This level of control precision is particularly advantageous in applications where precise speed synchronization, timing, or regulation is critical, such as in robotics, conveyor systems, or automated manufacturing processes.

By providing adjustable speed control, continuous speed variation, energy efficiency, load adaptation, and control precision, variable pulleys play a vital role in achieving variable speed control in machinery. Their flexibility and ability to fine-tune speed ratios contribute to improved performance, productivity, and efficiency in various industrial and mechanical applications.

In which industries and applications are variable pulleys commonly used?

Variable pulleys, also known as variable speed pulleys or variable drive pulleys, find extensive use in various industries and applications due to their ability to provide adjustable speed ratios. Here are some industries and applications where variable pulleys are commonly employed:

1. Automotive Industry:

Variable pulleys are widely used in automotive applications, particularly in continuously variable transmissions (CVTs). CVTs use variable pulleys to provide seamless speed adjustments, optimizing engine performance and fuel efficiency. They allow the engine to operate at its optimal speed for different driving conditions, resulting in smoother acceleration, improved fuel economy, and reduced emissions.

2. Manufacturing and Industrial Machinery:

In manufacturing and industrial settings, variable pulleys are utilized in various machinery and equipment. They are employed in conveyor systems, where they enable speed control to match the production requirements. Variable pulleys are also used in milling machines, lathes, and other machining equipment, allowing operators to adjust spindle speeds for different materials and cutting operations.

3. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems often incorporate variable pulleys in their fan and blower motors. By adjusting the pulley position, the speed of the fan or blower can be controlled to maintain the desired airflow and temperature regulation. This enables energy efficiency and precise climate control in residential, commercial, and industrial HVAC applications.

4. Agricultural Equipment:

Variable pulleys are utilized in various agricultural machinery, such as combine harvesters, tractors, and irrigation systems. They allow farmers to adjust the speed of different components, such as the harvesting mechanisms or water pumps, according to the specific requirements of the task or crop. Variable pulleys contribute to efficient agricultural operations and optimal utilization of resources.

5. Exercise Equipment:

In the fitness industry, variable pulleys are commonly found in exercise equipment like treadmills, elliptical trainers, and stationary bikes. These pulleys allow users to adjust the resistance and speed of the equipment, providing customizable workout intensity and accommodating different fitness levels.

6. Material Handling Systems:

Variable pulleys are utilized in material handling equipment, such as conveyors, lifts, and cranes. They enable precise speed control, allowing for efficient movement of goods and materials in warehouses, distribution centers, and manufacturing facilities.

7. Power Transmission Systems:

Variable pulleys play a crucial role in power transmission systems, where adjustable speed ratios are required. They are employed in applications like industrial pumps, compressors, and generators, allowing for flexible speed control and optimal performance.

These are just a few examples of the industries and applications where variable pulleys are commonly used. Their versatility and ability to provide adjustable speed ratios make them valuable components in numerous mechanical systems, contributing to improved efficiency, performance, and control.

editor by CX

2023-10-08